Sisal and sisal-cloth disks

Sisal cord for cutlery

Typical Applications:

- sisal cord brushes with medium hard impregnation are also suitable for processing decorated flat sufaces

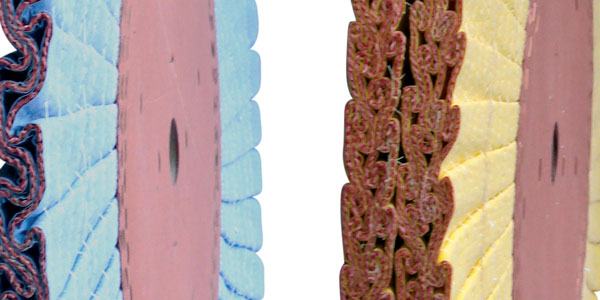

Pleated sisal-cotton disk

Typical Applications:

- flat part processing typically iron or stainless steel

- aluminium

- household appliance manufacturing

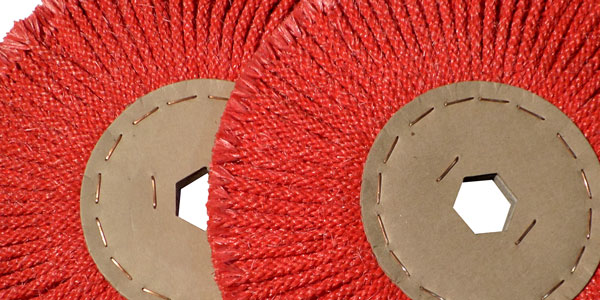

Sisal Cord

Typical Applications:

- cutlery processing

- polishing of pots and pans

- polishing of steel tubes

- steel surfaces processing

Sisal (Segments Construction)

Typical Applications:

- flat part processing, typically iron or stainless steel

- processing aluminium, non-ferrous metals

- external polishing of pots and pans

- brushing steel tubes

Ondulated Sisal Cotton Disk

Typical Applications:

- cutleryprocessing

- polishing of pots and pans

- polishing of steel tubes

- steel surfaces processing

Pleated Sisal Cloth Disk

Typical Applicatons:

- flat part processing typically iron or stainless steel

- aluminium

- household appliance manufacturing

Ventilated Sisal Cotton Disk

Typical Applications:

- aluminium and non ferrous metals polishing

- hardware buildings

- car parts

- household appliance manufacturing

Compact Sisal Disk

Typical Applications:

- flat part processing, typically iron or stainless steel

- processing aluminium, non ferrous metals

- external polishing of pots and pans

- brushing steel tubes