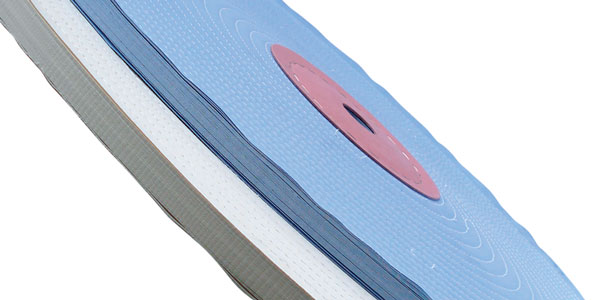

Cotton disks

The materials used for our cleaning tools are carefully selected and subjected to continuous monitoring to ensure consistency.

Typical Applications:

- sanitary fittings processing

- builders hardware manufacturing

- profiled parts finishing

- round parts finishing

The materials used for our cleaning tools are carefully selected and subjected to continuous monitoring to ensure consistency.

Typical Applications:

- pots and pans finishing

- hallowware processing

- sanitary fittings finishing

- car parts

- builders hardware processing

- woodworking

The materials used for our cleaning tools are carefully selected and subjected to continuous monitoring to ensure consistency.

Typical Applications:

- pots and pans finishing

- hallowware and flat parts

- no open single piece

The materials used for our cleaning tools are carefully selected and subjected to continuous monitoring to ensure consistency.

Typical Applications:

- pots and pans finishing

- hallowware and flat parts

- no open single piece

The materials used for our cleaning tools are carefully selected and subjected to continuous monitoring to ensure consistency.

Typical Applications:

- cutlery and utensil finishing

- dental use

- jewellery and watchmaking

- knife blade finishing

The materials used for our cleaning tools are carefully selected and subjected to continuous monitoring to ensure consistency.

Typical Applications:

- finitura di pentolame

- articoli cavi

- finitura di sanitari

- processi su parti di automobili

- processi su meccanismi di costruzione

- profilati alluminio

- finitura di tutti i materiali

The materials used for our cleaning tools are carefully selected and subjected to continuous monitoring to ensure consistency.